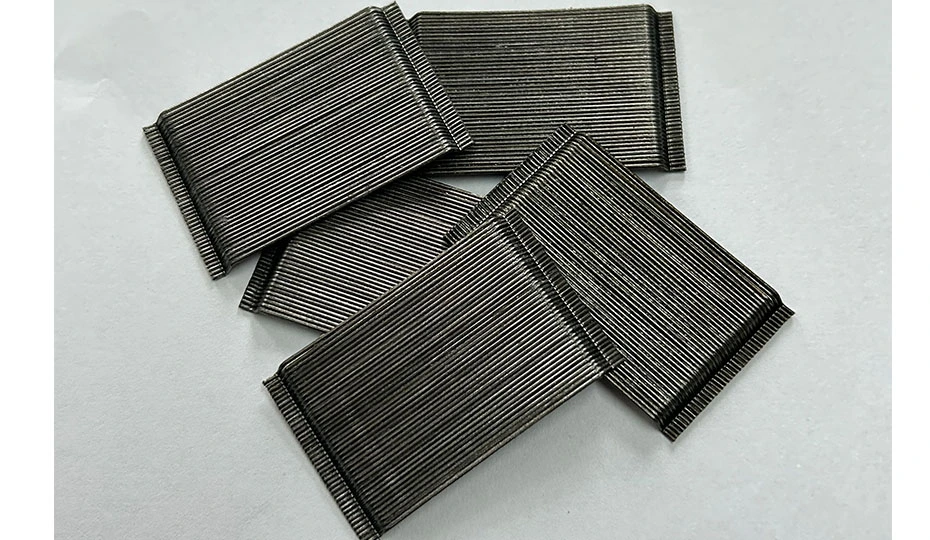

There are many types of steel fibres used in concrete. The steel fiber for concrete reinforcement is a new kind of metal material, in order to enhance concrete with metal fiber and shotcrete in its hardened state. Tengzhou SDS steel fibers make concrete have extremely high flexural strength and shear strength, and have good toughness, crack resistance, earthquake resistance, seepage control, and other functions. Widely used in industrial factory floors, highways, high-speed rail, bridges, airports, tunnels, water conservancy, electric power, municipal engineering, etc. The company has passed ISO9001 certification, and its products are exported to Southeast Asia, Europe, America and etc. Welcome to contact us for more information about steel fibers for concrete reinforcement.

English

English 한국어

한국어 français

français Deutsch

Deutsch русский

русский português

português العربية

العربية tiếng việt

tiếng việt ไทย

ไทย Polska

Polska Nederland

Nederland